Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

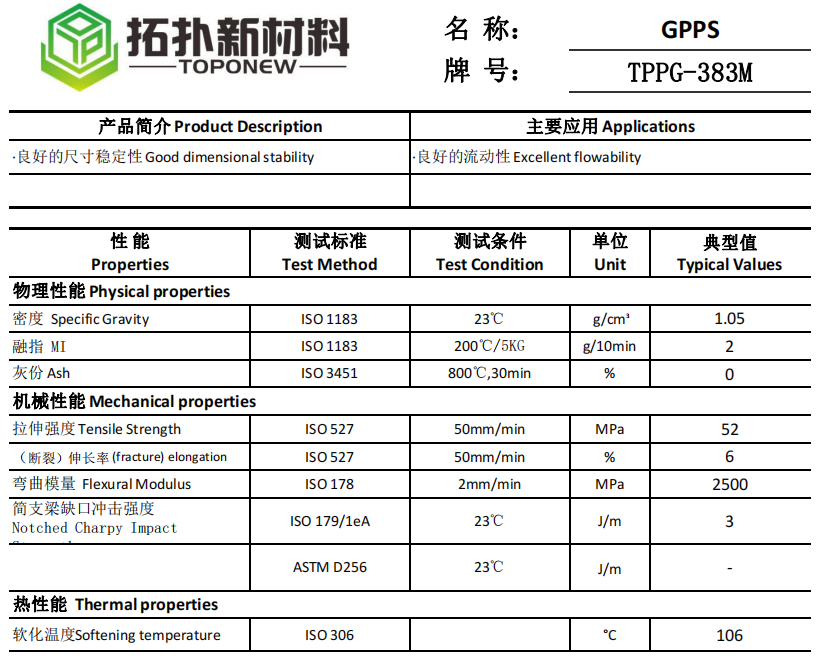

GPPS TPPG-383M

MI: 2 g/10min

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of GPPS TPPG-383M

Crystal Polystyrene GPPS Polymer Resin

General Purpose Polystyrene Properties

-

Transparency: GPPS is a clear and transparent plastic, allowing for visibility of contents inside packaging or products made from it.

-

Rigidity: GPPS is a stiff and rigid plastic, making it suitable for applications requiring structural integrity.

-

Brittle: GPPS is relatively brittle and can break or shatter easily when subjected to impact or stress. This property makes it less suitable for applications that require high durability.

-

Processability: GPPS has good processability and can be easily molded or extruded into various shapes and forms. It has a low melting point, making it suitable for injection molding processes.

-

Lightweight: GPPS is a lightweight plastic, making it useful for applications where weight is a consideration, such as packaging materials.

-

Electrical insulation: GPPS is an effective electrical insulator, making it suitable for applications in the electrical and electronics industry.

-

Chemical resistance: GPPS has limited resistance to certain chemicals and may become damaged or degraded when exposed to solvents or strong acids.

General Purpose Polystyrene Applications:

-

Packaging: GPPS is extensively employed in packaging applications due to its excellent transparency, rigidity, and ease of molding. It is used for manufacturing food containers, disposable cutlery, drink cups, clamshell containers, cosmetic packaging, CD/DVD cases, and protective packaging materials.

-

Consumer Products: GPPS is utilized in the production of numerous consumer goods. It is commonly found in household items such as hangers, storage boxes, office supplies, and toys. GPPS's combination of rigidity and lightweight nature makes it suitable for manufacturing a wide variety of consumer products.

-

Electrical and Electronic Components: GPPS's exceptional electrical insulating properties make it a preferred material for electrical and electronic applications. It is used in the production of switch housings, sockets, connectors, and insulating components in appliances, electronic devices, and automotive electronics.

-

Display and Signage: GPPS's transparency and ability to maintain its clarity over time make it well-suited for displays and signage. It is commonly employed in point-of-sale displays, advertising signage, lightboxes, and merchandising displays.

-

Stationery and Office Supplies: GPPS is utilized in the manufacturing of stationery items such as pen barrels, rulers, stapler bodies, and binder covers. Its rigidity and ease of customization make it a popular choice for various office supplies.

-

Medical Equipment and Devices: GPPS finds applications in the medical field for non-implantable medical equipment. It is used for the production of petri dishes, diagnostic test kits, disposable medical components, sample containers, and surgical instrument casings.

-

Automotive Industry: GPPS is employed in the automotive industry for non-load-bearing parts that require good aesthetics and resistance to chemicals. It is used for interior trim, dashboard components, glove box lids, center console panels, and door handles.

-

Construction and Building Materials: GPPS is utilized in the construction industry for various applications, including light diffusers in suspended ceilings, architectural models, window profiles, and decorative trim.

-

Educational Materials: GPPS is commonly used in educational settings for items like school rulers, geometry sets, and models due to its ease of molding and ability to produce precise shapes.

-

Filament for 3D Printing: GPPS resin is increasingly used as a filament material in 3D printing due to its ease of melting, good flow properties, and cost-effectiveness.

These are just a few notable applications of General Purpose Polystyrene GPPS, and its versatility continues to find new uses in different industries. We are high quality GPPS Granules Supplier, and if you are interested about the GPPS granules, please feel free to contact us.

Download

-

TOPO-GPPS TPPG-383M NA.pdf

Download TOPO-GPPS TPPG-383M NA.pdf